Model M2 - Status Quo, Part 2

A look behind the scenes - Part 2

In our last report we showed the development and concept changes that Model M2 has undergone since autumn 2019. In this part we want to go into further adjustments and details of the design.

The last team member is found

For some time now, the drivers to be installed had been fixed, i.e. the compression driver with 44 mm titanium diaphragm from Model M1 as tweeter, as well as a long-stroke 10″/25 cm bass/midrange driver at the front with compact neodymium magnet. Only the rear driver had to be found due to the decision to change from 10″/25 cm to 10″/30 cm(read the previous report). Such an evaluation is preceded by the definition of the concrete requirements and the screening of the suppliers and models in question. In the end, four candidates were left over, which we tested in our laboratory up to the large signal range (Klippel LSI):

After extensive series of measurements - the white dots on the dust caps provide the reflection surface for the laser of the Klippel LSI measuring system - the decision was made in favor of a German make (bottom left), since only this model offered the largest linear travel (+/- 13 mm), lowest distortion due to triple demodulation and resonance-free operation up to over 500 Hz.

Extreme conditions

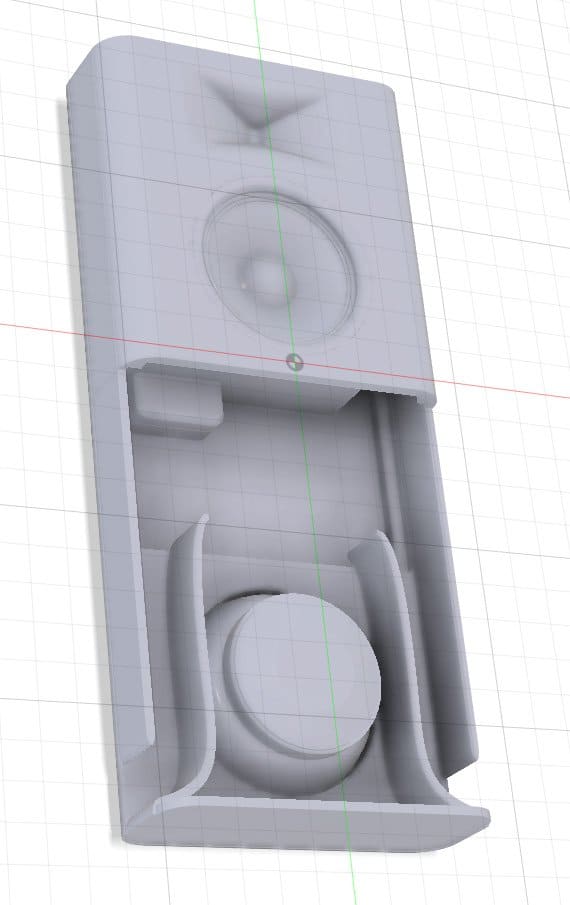

The next step was to find a working bass reflex tuning. Our goal was to create a low tuning from a very compact cabinet, but one that works absolutely noise-free and without resonance in any load range. From the preceding simulations, a contour of the tunnels ("ports") was aerodynamically optimized accordingly in order to produce no noise despite the high flow velocity. For this purpose, the exits of the tunnels were each led laterally downwards into the base of the stand.

Despite these measures, it was not possible to achieve a reproduction free of background noise in the final load range - corresponding to approx. 1000 W and 115 dB (!). Admittedly, these load tests are extreme, but they also illustrate our demand for error-free reproduction in all operating conditions.

As a result, the entire tunnel route was redesigned and further measures were taken:

- The entire cabinet was enlarged by approx. 10% from 1100 x 480 x 185 mm to now 1150 x 499 x 199 mm to create more acoustically effective internal volume. The aesthetic proportions have been retained.

- The tunnel dimensions were increased by approx. 15% and all jump points were removed.

- The exits of the two tunnels were now led into the bottom of the housing towards the ground. In order not to obstruct them, the whole box "floats" on four metal sleeves above a new base plate, which at the same time prevents the tilting moment and thus provides a stable stand(see pictures above, the "blue box")

- This base plate is part of the bass reflex tuning, because the air mass is also effective in the gap between the plate and the bottom of the cabinet.

Get the latest news from us direct to your mailbox

This form transmits your e-mail, so that we can send you the requested information. You can cancel the subscription at any time. In our Privacy policy learn more about this.